Everyone knows that to get the most out of your pumps, you need reasonable pulsation control. There have only been two choices for a pulsation control solution; gas-charged equipment or maintenance free equipment. Both of which have their own unique set of problems. Besides choosing which set of limitations you prefer, you are stuck with choosing one antiquated solution over another. Any of these choices could leave you unprepared for the next wave of technology.

The Problems With Pulsation Control

Limited Industry Choices

Before Sigma Drilling Technologies introduced new industry advancements, pulsation equipment choices were limited to either gas-charged or maintenance free units.

Gas-charged equipment is lightweight, has a small footprint, and can be installed directly off the manifold ports. The problem is, they require a great deal of expense and maintenance to run and work properly. Safety is also a significant factor when it comes to these units.

Maintenance free dampeners are inexpensive to maintain, don’t require regular service, and are considered safer. The problem with maintenance free equipment is that they are extremely heavy, dreadfully expensive, require an enormous amount of space, and usually need a significant redesign of the pump skid.

Acoustic Resonance

Appendage style dampeners will only reduce the low-frequency waves. On the other hand, the oversized and expensive maintenance free units have their own set of complications.

Traditional dampeners are installed above the flow line and can only reduce the larger, slower, low-frequency energy waves. They cannot truly mitigate the high-frequency energy waves produced by the pump because they are smaller, faster, and are too quick for a traditional dampener to react to, so these energies continue down the line. Most attempted solutions to this dilemma are incredibly costly. These maintenance free dampeners involve either reconfiguring your skid or adding a massive amount of size and weight to your rig.

Unprepared for the Future

As drill plans are advancing, wells are getting deeper, horizontal runs are getting longer, and the industry needs to meet more significant pressure requirements.

Mud pumps will get higher rated, and fluid ends will upgrade, which means existing pulsation equipment will need upgrading. As operational pressure demands increase, it will become imperative for contractors to either change or update their capital equipment.

Additionally, with oil prices endlessly fluctuating, contractors must make technological choices to decrease operational expenses. These choices need to place companies in a position of strength to gain an advantage.

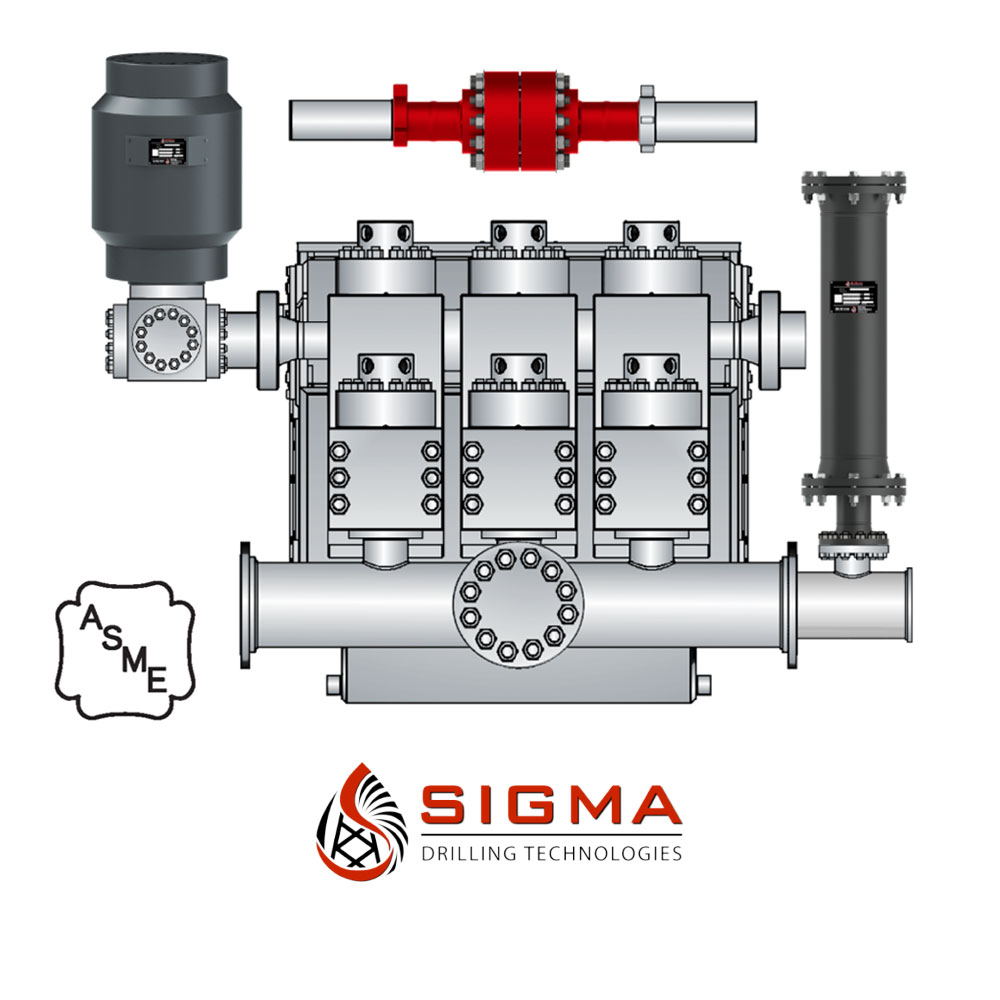

What Is The CFD System?

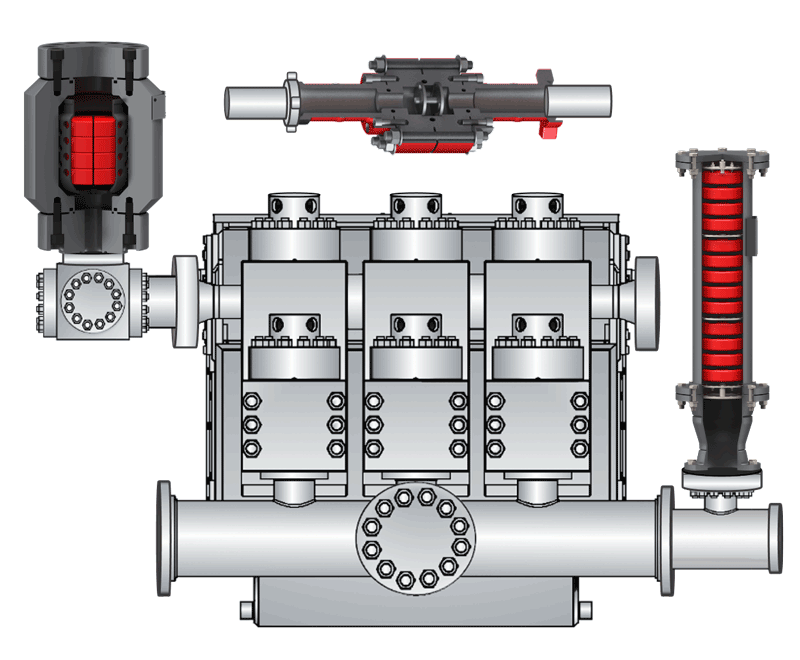

The Charge Free Dampening System™ solves the logistic concerns of cost, performance, size, weight, durability, and post dampener acoustic resonance.

The Charge Free Dampening System™ is the first and only complete dampening system designed for maximum performance and cost savings. With the highest pressure rating at 10,000 psi, the CFD System far surpasses any pulsation control equipment in the drilling market today. Sigma’s system utilizes both appendage and flow-through technologies and yet still maintains the most compact design.

This multistage system utilizes several of Sigma’s advanced products that are proven to maximize efficiencies and upgrade operations of any reciprocating pumping system by themselves.

By protectively coating both inside and outside the system’s Charge Free Stabilizer™ and the Charge Free Dampener™, the system is entirely corrosion-resistant. The Charge Free Dampening System™ is easily the most protected pulsation equipment available.

The advantage of the CFD System’s small size, durability, and performance is combined with the fact the system requires no gas charging. The utilization of the Charge Free Conversion Kit® maximizes the dampening effects of the system without the need for nitrogen charging.

The Charge Free Dampening System™ is categorically the most sophisticated pulsation control available for your rigs’ pumping operations. With the introduction of the CFD System, Sigma Drilling Technologies proves to be the authority on state-of-the-art advancements in pulsation control technologies.

Why The CFD System?

The Charge Free Dampening System™ or CFD System is a complete multistage system designed to mitigate both low and high-frequency energies produced by the reciprocating pump.

The complete Charge Free Dampening System™ is on the leading edge with a growing list of advantages and benefits.

- Performance consideration for both sides of the pump

- Highest pressure rated drilling dampener

- Smallest, lightest, and most versatile pump performance package on the market

- Most durable drilling pulsation dampening system available

- No nitrogen required on either side of the pump

Charge Free Stabilizer

The first stage utilizes Sigma’s revolutionary Charge Free Stabilizer™. The CFS is a versatile suction stabilizer using a multi-phase mitigation method. This method allows for both compression and kinetic exchange while isolating both the reciprocation pump and the charge pump, which provides higher performance and better longevity for both pumps.

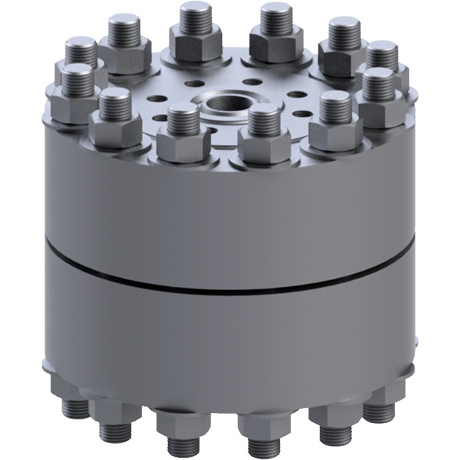

Charge Free Dampener

The next stage utilizes Sigma’s revolutionary Charge Free Dampener™. The CFD from Sigma is the only dampener on the market too, not only removes any requirement for gas charging but is the smallest and lightest drilling dampener available. The cutting edge design comes standard with a corrosion-resistant coating inside and out, creating another unparalleled product by Sigma Drilling Technologies.

Charge Free Conversion Kits

Inside the Charge Free Stabilizer™ and the Charge Free Dampener™ are the Charge Free Conversion Kits, the suction Charge Free Conversion Kit®, and the discharge Charge Free Conversion Kit®. These conversion kits are designed to eliminate the need for nitrogen gas charging while significantly improving performance. The discharge CFC Kit utilizes a molded basket containing a layered compression disc system, each of which comprises four wedges. The suction CFC Kit uses a compression column designed to maximize compression and kinetic exchange.

Acoustic Assassin®

The CFD System’s final stage, the Acoustic Assassin®, is a flow-through fixture, utilizing proprietary baffling technology. The unit solves the operation problems common to pumping systems experiencing high-frequency acoustic resonance. With the Assassin installed, your system absorbs significantly less energy and will last longer and perform better.

The Charge Free Dampening System™ by Sigma is the only system on the market of its kind. Now your pumping operations will surpass all others and outperform your expectations.