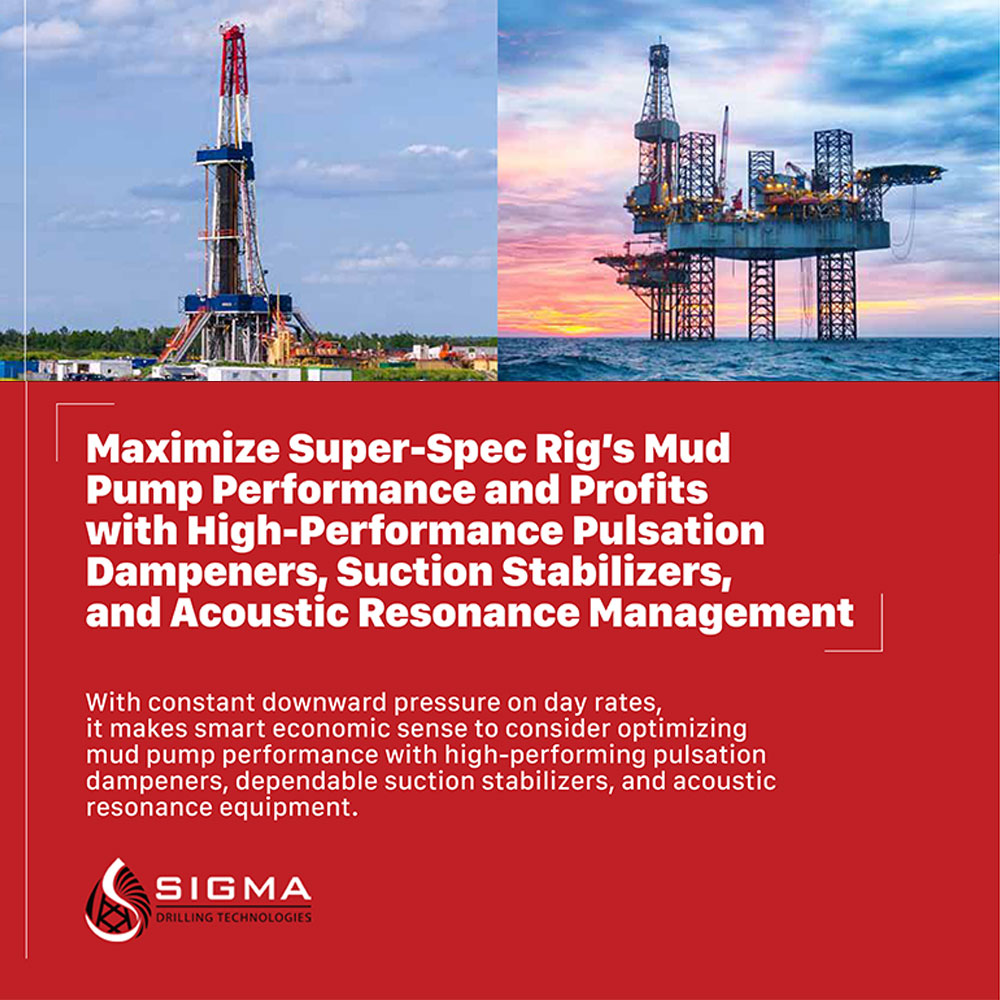

Constant downward pressure on day rates makes smart economic sense to consider optimizing mud pump performance with high-performing pulsation dampeners, dependable suction stabilizers, and acoustic resonance equipment. Enhancing mud pump performance is a cost-effective insurance policy to prevent expensive unplanned downtime and maximize drilling rig productivity and profits.

Pulsation Control minimizes structural piping stress, decreases repairs and expensive downtime

Maintaining a rig’s piping system’s structural integrity is directly dependent upon optimal pulsation dampener and suction stabilizer performance. If the pumping system runs smoothly, the piping system encounters minimal stress and vibration.

Conversely, when the mud pump’s energy mitigation systems are mechanically compromised, the piping system may undergo significant structural stress from excess vibrations. As a result, damage may occur in broken welds and piping joints, jeopardizing well-bore integrity. Ultimately the loss of the well’s integrity can mean catastrophic financial loss for the contractor and operator, not to mention a compromised piping system that places team members and other equipment in harm’s way. The goal for every drilling rig is to successfully and safely deliver a planned well.

Pulsation dampeners improve hydraulic system performance and extend pump longevity

Investing in high-performance pulsation dampeners is essential to regulate pulsation on a system’s positive displacement pump to assure the most efficient operation with minimal stress and vibration placed on system piping.

The use of high-performance pulsation dampeners extends the pump’s longevity, which can be a significant benefit in cost savings over time, as mud pump purchase prices circa 2020 start around $100,000 at the low end.

Current pulsation dampener choices range from 60-year-old technologies to state of the art control systems.

The industry’s most advanced pulsation dampener choice, Sigma’s 10,000 psi-rated Charge Free Dampener™, utilizing both a kinetic energy exchange and compression systems, offers the most advantages for maximizing a super-spec rig’s mud pump performance.

With the highest pressure rating of all drilling pulsation dampeners, it also has the smallest environmental footprint and weight. The CFD is entirely corrosion-resistant, inside and out, and comprised of forged American steel that carries the American Society of Mechanical Engineering’s stamp of approval. The Charge Free Dampener™ doesn’t use any gas charging, so maintenance is simple, worry-free, and cost-effective.

Suction stabilizers prevent cavitation and pump chatter – decrease downtime, system repair/replacement costs

An often-overlooked element in managing mud pump performance is optimizing the pump’s suction or supply side.

Ensuring suction ports have an optimum fluid supply is the first step in cavitation prevention. Installation of a dependable suction stabilizer at the suction manifold port provides an adequate pumped fluid volume to prevent cavitation.

A well-placed suction stabilizer can also prevent pump chatter. Pump chatter occurs when energy is exchanged between the quick opening and closing of the reciprocating pump’s valves and the hammer effect from the centrifugal pump. Pump isolation with suction stabilizers is achieved when the charge pumps are isolated from reciprocating pumps and vice versa. The results are a smooth flow of pumped media devoid of agitating energies present in the pumped fluid.

The net benefit, extended longevity for pump expendables, is due to the suction stabilizers’ energy isolation.

Suction stabilizer units can mitigate most of the challenges related to pulsations or pressure surges, even in the most complex piping conditions. The resulting benefits prevent expensive unplanned downtime and decrease costs and inconvenience associated with system replacements and repairs.

Many different suction units are available in the industry and vary in performance results, ease of use, and reliability.

Sigma’s Charge Free Stabilizer™ offers the most advanced technology, versatility, and best performance available in today’s market. It provides energy reduction without gas charges and virtually eliminates premature failure.

The patent-pending design effectively manages energy mitigation through a dual system of compression and kinetic exchange.

High-frequency energy signature reduction extends system longevity and increases operational efficiency

Sometimes, even with reasonable pulsation control, the mud pump and piping system experience vibration and turbulence caused by acoustic resonance from worn valve seals, worn packing, or something as minute as the mud pump being unlevel on its skid.

Known as the “Silent Killer”, excessive acoustic resonance can significantly compromise the pipe’s integrity and wreak havoc on downhole tools causing increased downtime and costly repairs. Other challenges include premature failure of pumping and pulsation equipment, signal sync problems, and excessive pipe vibration.

Although Sigma Drilling Technologies’ Charge Free Conversion Kit® reduces acoustic resonance significantly, some systems have tremendous acoustic signatures. The Acoustic Assassin® effectively reduces a reciprocating pump’s high-frequency energy signatures via an inline system that baffles acoustics.

As pumped media is moved through the internal baffling system of the Acoustic Assassin®, the customizable flow though unit reorders the acoustic signatures, detuning the system with a massive reduction in energy.

Various baffling systems and chamber configurations can conveniently customize any pumping system,5,000 PSI and higher.

High-performance equipment reduces system noise, decreases downtime, and optimizes drilling time

Upgrading your super-spec rig with Sigma Drilling Technologies’ Pulsation Dampeners, Suction Stabilizers, and Acoustic Filters will significantly reduce system noise, decrease downtime, and optimize drilling time. The noise reduction supports superior signal detection for MWD. As a result, drilling can continue uninterrupted, and downtime is typically reduced by an hour as mud pumps do not have to be stopped due to low signal transmission.

High-performance pulsation equipment significantly improves rig safety

Using Sigma Drilling Technologies’ Charge Free Pulsation Dampeners and Suction Stabilizers eliminates the chance of dangerous accidents that can occur with gas-charged pulsation dampeners and suction stabilizers installed on high-pressure mud pumps. For example, when gas bottles entirely or partially filled with oxygen are mistakenly used to pre-charge the pulsation dampeners, catastrophic explosions are likely.

Summary

Given today’s tremendous economic pressure for increasing efficiency and maximizing drill plan profits, many contractors may find it makes smart financial sense to invest in high-performance Pulsation Dampeners, Suction Stabilizers, and Acoustic Resonance Management equipment to optimize their super-spec rigs’ mud pump performance.